The application of roller press technology began in the 1980s. This technology is mainly used in the cement industry and the ore industry, and has gradually become a key component in the production process. The core components of the roller press are two rollers, which are currently rolled on the market. The roller of the machine is mostly the surface of the surfacing roller and the surface of the centrifugal casting composite roll.

Since the roller is directly in contact with the material, under the strong pressing force , the roller surface will be subjected to severe abrasive wear and furrow wear, and the roller surface will be squeezed. The pit phenomenon, these accumulated pits can cause fatigue wear of the roll surface material, which seriously affects the normal operation of the equipment.

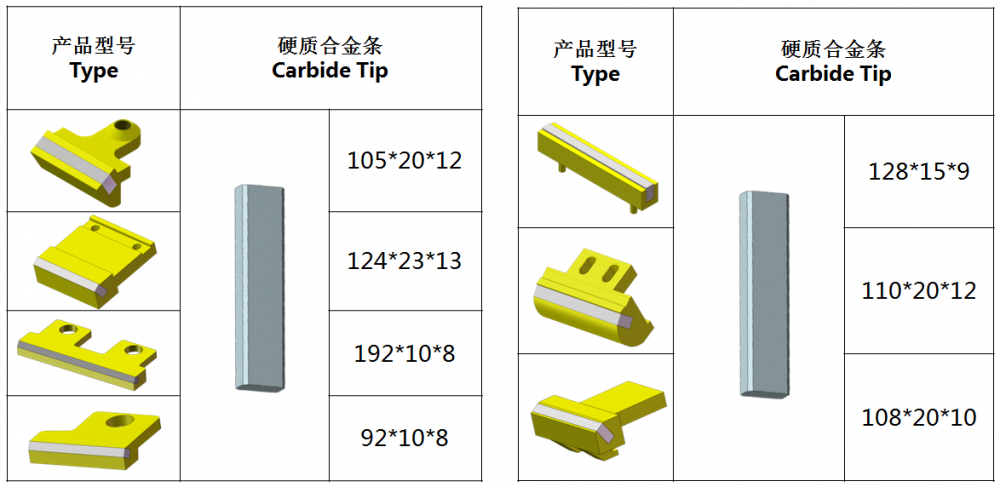

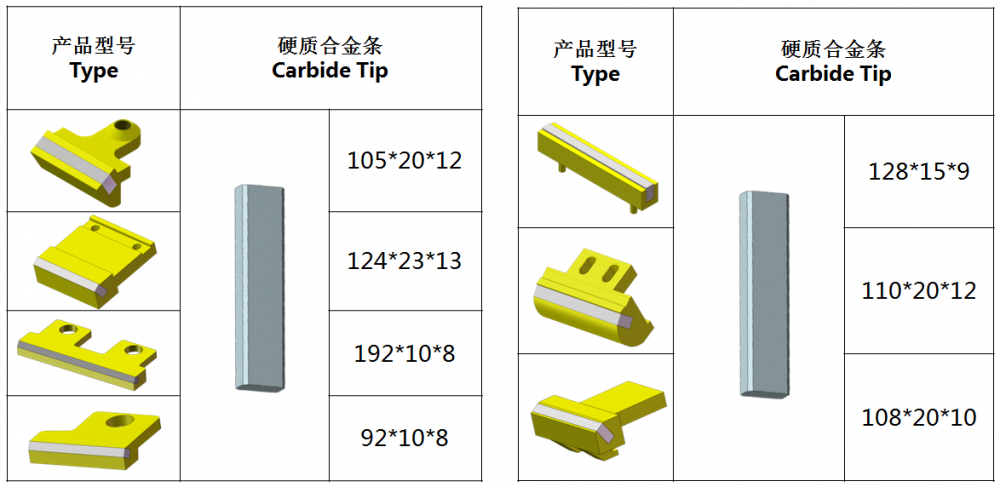

Recommend Products

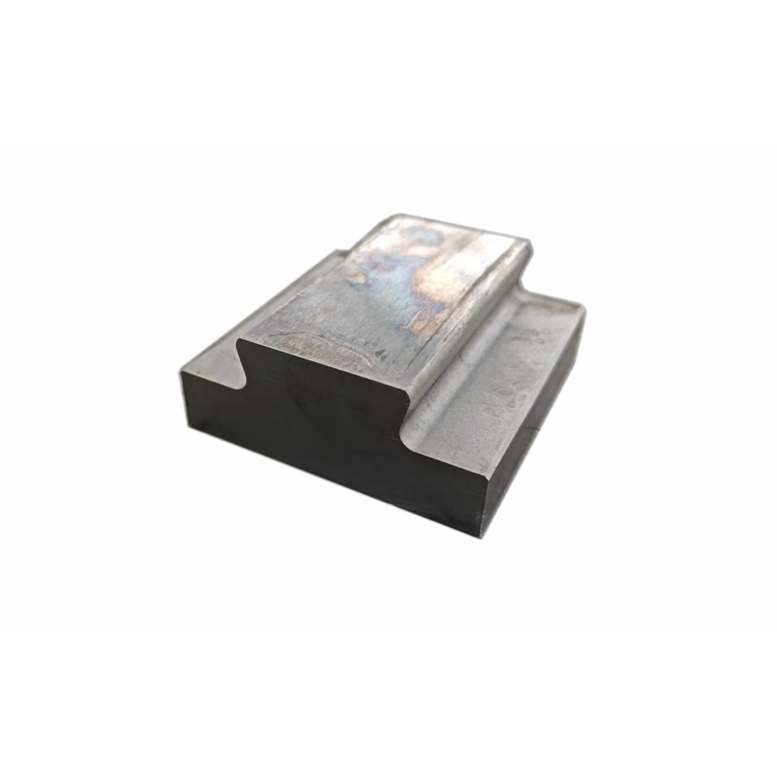

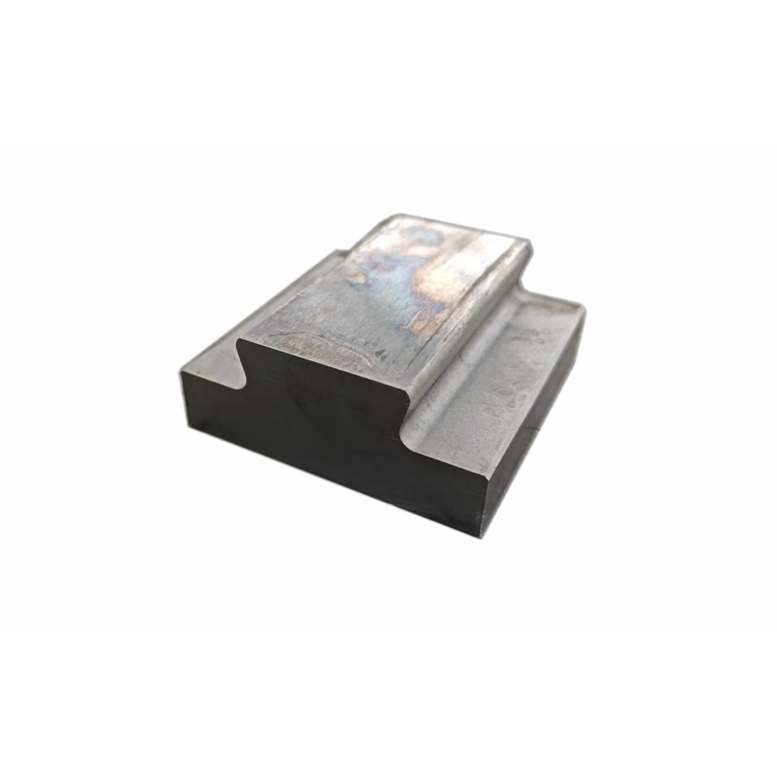

1. Side Stud

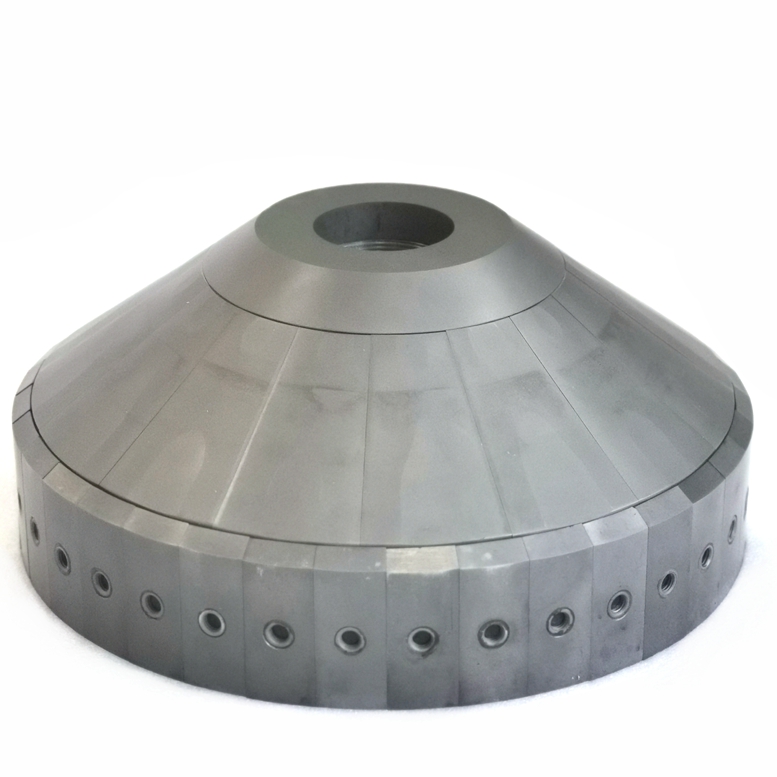

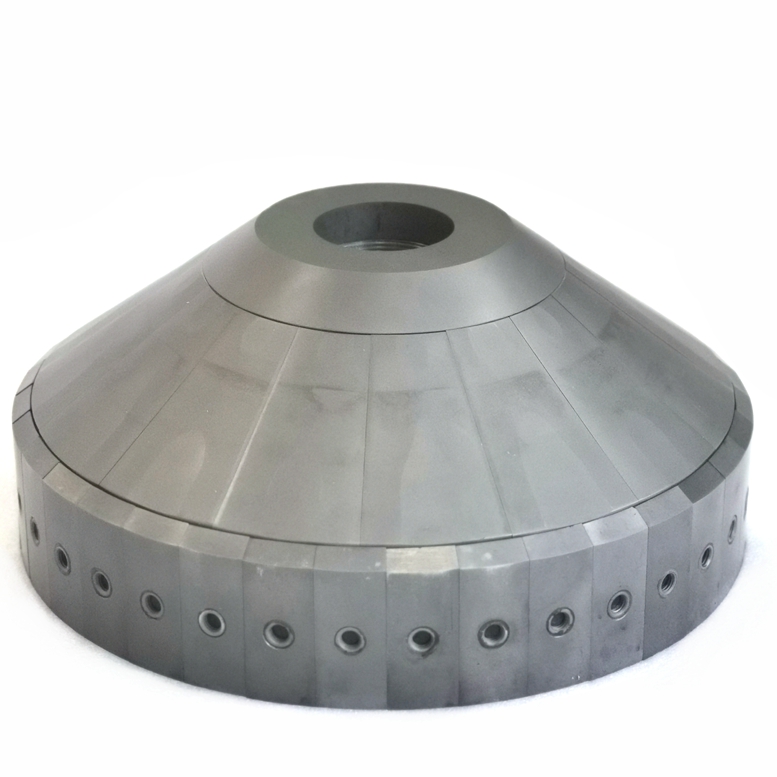

2. Rotor Tip Set

3. Distributor Plate