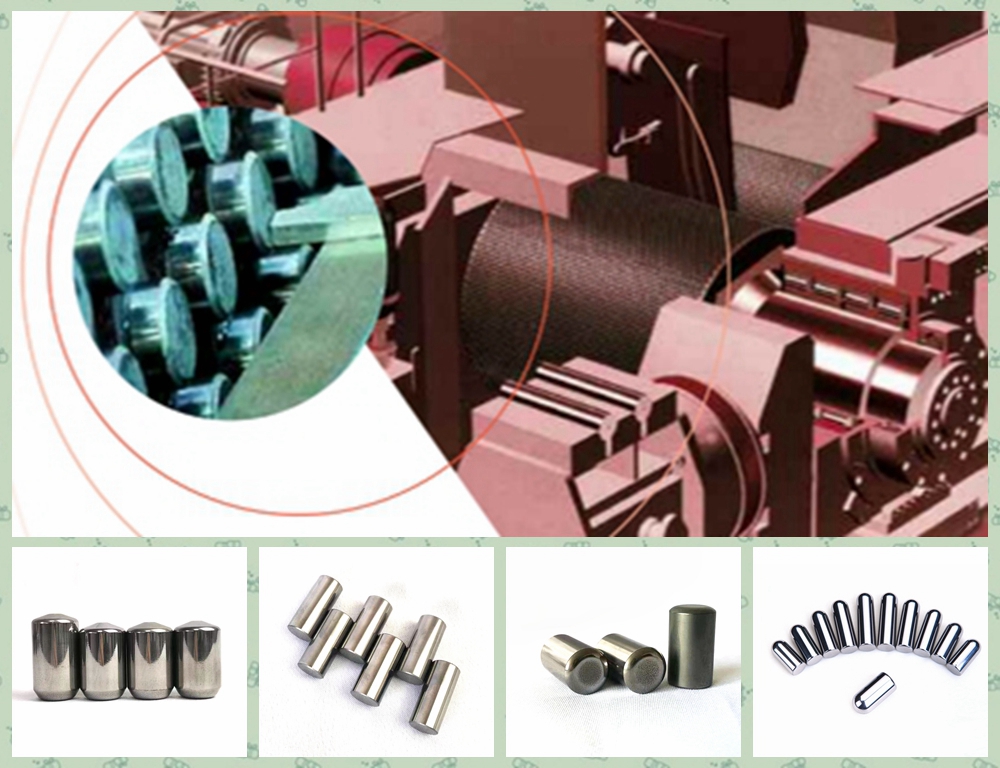

The HPGR (High Pressure Grinding Roller) button roller is an innovative and efficient technology widely used in the mining and cement industries. Tungsten carbide studs, predominantly employed in roller presses, significantly enhance the wear-resistance of roller surfaces as compared to traditional overlay materials. This technological advancement not only fortifies the roller face against abrasion but also extends the overall service life of roller presses. Characterized by unparalleled hardness, remarkable strength, and exceptional impact tolerance, these studs have demonstrated an over tenfold increase in the longevity of the surfacing material, thereby maximizing operational efficiency and reducing maintenance costs.

Hard Alloy Stud for hpgr roller iron ore mining

The performance of its carbide studs determines the operating conditions of the roller press.

The good operation of the roller press requires high-quality cemented carbide HPGR grinding roller studs.

Key features for HPGR grinding roller tyre carbide buttons:

- Exceptional Wear Resistance: Cemented carbide studs demonstrate an unmatched ability to withstand wear and tear, ensuring prolonged durability and reduced downtime.

- Unparalleled Hardness: Boasting superior hardness, these studs offer a robust solution that stands up to the toughest industrial applications, maintaining their integrity under high-stress conditions.

- Precision Engineered: Crafted with meticulous attention to detail, every aspect of these studs is precisely engineered to ensure optimal performance and seamless integration with roller presses.

- Significantly Extended Service Life: By significantly extending the service life of roller presses, tungsten carbide studs offer a cost-effective solution that minimizes maintenance requirements and maximizes operational efficiency.

Common tungsten and carbide material grade:

| Material Tungsten Carbide Grade for Wolfram carbide Pin Stud |

| Grade | Density g/cm3 | Hardness HRA | TRS >N/mm2 | Chemical Composition Co% | Coercivity kA/m |

| YG8 | 14.62-14.82 | 89.5-91.0 | 1800 | 7.7-8.2 | 10.0-15.5 |

| YG8C | 14.6-14.8 | 87.5-89 | 2000 | 8-8.5 | 6.3-9.3 |

| YG10C | 14.35-14.55 | 87.0-88.5 | 2150 | 10.0-10.5 | 5.8-9.3 |

| YG15 | 13.95-14.15 | 87.0-88.5 | 2300 | 14.1-14.8 | 7.0-10.0 |

| YG15C | 13.9-14.1 | 85-86.5 | 2300 | 14.7-15.3 | 4.5-6.5 |

Standard export packing, suitable for ocean vessel transportation:

Zigong Tianyi Industry Co., Ltd. is a renowned manufacturer and exporter specializing in the design, innovation, and fabrication of high-performance carbide-studded rollers for HPGR (High Pressure Grinding Rolls) systems and carbide wear parts for VSI (Vertical Shaft Impactor) crusher rotor tip set, distributor plate. Catering to various industries including engineering, construction, and beyond, the company offers tailored solutions that meet the most demanding requirements for durability, efficiency, and longevity. If you are looking for high-quality products in the field of high-pressure roller press machines, look no further than Zigong Tianyi Industry Co., Ltd. Contact us today to learn more about our products and how we can help you with your specific needs.