Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

(1) Description of abnormal situation of T company

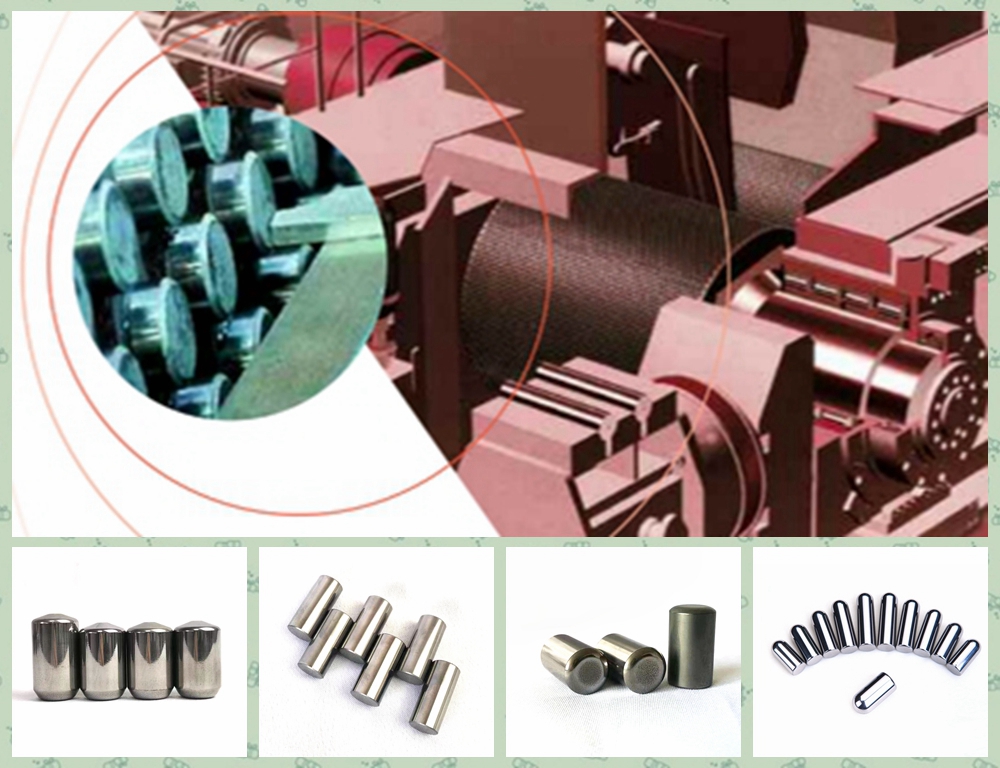

The vertical down-feed pipe between the roller press and the weighing bin at T Company was of insufficient height, resulting in low working pressure within the roller press, compromised extrusion efficiency, high sieve residue of incoming material, reduced fine powder content, lower system output, and higher grinding power consumption.

T Company's Grinding System Configuration:

120-50 roller press (material throughput: 165t/h, main motor power: 2 × 250kw-10kv-21A)

550/120 dispersing classifier (processing capacity: 140-175t/h, total motor power for dispersing + classifying: 45kw + 30kw)

Φ3.2×13m three-chamber open-circuit tube mill (main motor power: 1600kw-10kv-110A, grinding media loading: 127t, chamber lengths: 3.25m, 2.50m, 6.50m respectively, + 550mm height activation rings in four circles, working speed: 17.6r/min)

Mill tail dust collector fan, forming an open-circuit combined grinding system

Production Target:

P.O42.5 grade cement (finished product specific surface area ≥ 380±10m2/kg)

System output: 65t/h

Grinding power consumption: 35kwh/t

Observed Abnormalities and Consequences:

R80μm sieve residue of incoming material: 78.7% (fine powder < 80μm: only 21.3%)

High coarse particle content in finished cement sieve residue

Untapped potential for increasing system capacity

Need to reduce grinding power consumption

Technical Diagnosis Analysis:

The height of the vertical down-feed pipe between the roller press feed plane and the weighing bin was less than 1.2m, causing low material pressure within the pipe, frequent adjustments to the rod valve, and segregation or collapse of material in the weighing bin, leading to significant dust in the production area.

Severe wear and leakage at the side plates of the roller press resulted in a low working pressure of only 6.0 MPa to 6.5 MPa, directly impacting material extrusion effectiveness and reducing the fine powder content (< 80μm) in the output.

Technical Measures Adopted and Their Effects:

During the annual overhaul, the height of the elevator and weighing bin was increased, simultaneously raising the vertical down-feed pipe height to 2.5m.

The roller press side plates were repaired through surfacing welding to reduce edge leakage.

During operation, the weighing bin material level was maintained at 60%-70% to eliminate segregation and collapse, ensuring a stable material pressure and column in the vertical down-feed pipe, significantly improving workplace hygiene.

The roller press working pressure was adjusted from 6.0 MPa to 6.5 MPa to 7.2 MPa to 7.5 MPa, enhancing extrusion efficiency. After classification by the dispersing classifier, the R80μm sieve residue of incoming material dropped from 78.7% to 49.8% (fine powder < 80μm reached 50.2%), a reduction of 28.9% in sieve residue (i.e., a 28.9% increase in fine powder content in incoming material). There were virtually no coarse particles in the sieve residue.

Production of P.O42.5 grade cement reached a system output of 79t/h, with grinding power consumption reduced to 26.4kwh/t.

Benefits of the Modification:

Annual electricity savings of 4.8 million kWh, translating to over 2.8 million yuan in savings, based on an annual production of 600,000 tons.

...to be continued

September 20, 2024

September 13, 2024

Talisman Mining has confirmed that it has made a greenfield base metal-precious metal discovery at the Durnings prospect of its Lachlan exploration project in central New South Wales. On the north...

Bolivia and China are actively expanding cooperation in the field of mining. Recently, Chinese Ambassador to Bolivia Wang Liang has called on the President of the National Lithium Company of Bolivia...

Argentina's Ministry of Mines expects the country's copper exports to increase to $5 billion by 2030, when seven projects will come on line, according to the BNAmericas website. The seven projects,...

According to the Mining.com website, citing Reuters, the world's largest copper producer, Chile's National Copper Commission (Cochilco), released data on Friday showed that the country's copper...

Email to this supplier

September 20, 2024

September 13, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.