The side baffle of the press can prevent the end face of the roller from leaking and improve the extrusion effect, but it is also one of the most important wearing parts of the roll press. Therefore, it is of great significance to master its wear mechanism and take corresponding anti-wear measures to improve the extrusion effect, improve the mill production quality and extend the service life of the side baffle.

HPGR is more and more widely used, but there is also a problem of fast wear in the process of use, the most important wearing part is the surface and side baffle, especially the side baffle, when the roller press line or pattern wear is very small, the side baffle has been worn. From the actual use of the situation, in the early days of use, the service life of the side baffle is only about a week, and the long life is 1 month. After the side baffle fails, if it is not replaced in time, the material will leak from the end face of the roller, resulting in edge effect, which makes the extrusion effect worse and increases the cycle load. In addition, if the side baffle is used improperly, such as the improper adjustment of the gap or the side baffle is not replaced in time after wearing through, it will also cause abnormal damage to the end face of the roller and reduce the width of the roller, which will also affect the extrusion effect. Therefore, it is of great significance to master the damage mechanism of the side baffle and strengthen the parts that are easy to wear in order to improve its service life, improve the extrusion effect, improve the mill production quality and better play the role of the roller press.

Wear mechanism

The roller press is to crush the material through the material layer extrusion principle. The material is added from the feeding device, under the gravity of the material and the rotation of the two rollers, the material is first compacted, and then advances downward. After entering the pressure area, due to the gradual increase of pressure, the pressure reaches the maximum at the smallest place between the two rollers, the material is broken or a large number of micro-cracks are generated. After the material particles are squeezed, the density is higher, the material cake is formed and discharged from the lower part of the roller. Therefore, in the roller press, the material actually passes through three stages, namely, the compaction stage, the extrusion stage, and the expansion stage (the volume will be slightly increased after discharge).From the working principle of the roller press, it can be seen that the side baffle is directly in contact with the material, and its wear is typical abrasive wear, but in different areas, the severity of wear is different. The working area of the side baffler can be divided into two areas, that is, in the AB area, because the force of the material is not large, it belongs to the weak material wear area; in the BC area, the material is subjected to high extrusion pressure, and part of the material will be extruded from the two rolls, so the high-pressure abrasive wear area is in this area. In the area below BC, although the pressure is reduced, the extrusion dense material must be discharged, so it is also a strong abrasive wear area. Therefore, in order to make the side baffle wear, it is necessary to use high hardness wear-resistant materials for the BC region.

Anti-wear measures

To improve the wear resistance of the material, the general measures are: the use of ordinary pre-ground steel plate.The use of wear-resistant castings using carbide and the use of composite wear-resistant steel, from the current use, the use of composite wear-resistant steel is the best effect.

Use summary

1.Improving the hardness of easy wear parts is an effective measure to improve the service life of the side baffle, from the use of materials, the side baffle made of composite wear-resistant steel plate is the best effect. Although the hardness of cemented carbide is higher, but considering the safety and reliability of the side baffle structure, we advocate the use of integral structure rather than the use of bolted combined structure.

2.When the composite wear-resistant steel plate is used to make the side baffle, it is necessary to pay attention to the welding stress and avoid the deformation of the side baffle, because the gap between the side baffle and the end face of the roller is uneven after the deformation, and the force on the top rod will be uneven and difficult to adjust.

3.In order to improve the service life of the side baffle, it is necessary to adjust the clearance between the side baffle and the end face of the roller.The gap is too small, it is easy to rub the end face of the roller, so that the wear-resistant layer of the end face of the roller falls off, and the gap is too large, it is easy to material, and the material stop effect is not achieved.

This chapter ends here, if you want to know more about our products, you can click into our independent station to send inquiries, we have a special person will communicate with you in the first time.Zigong Tianyi Industrial Co., Ltd. - Your trusted partner for high-quality

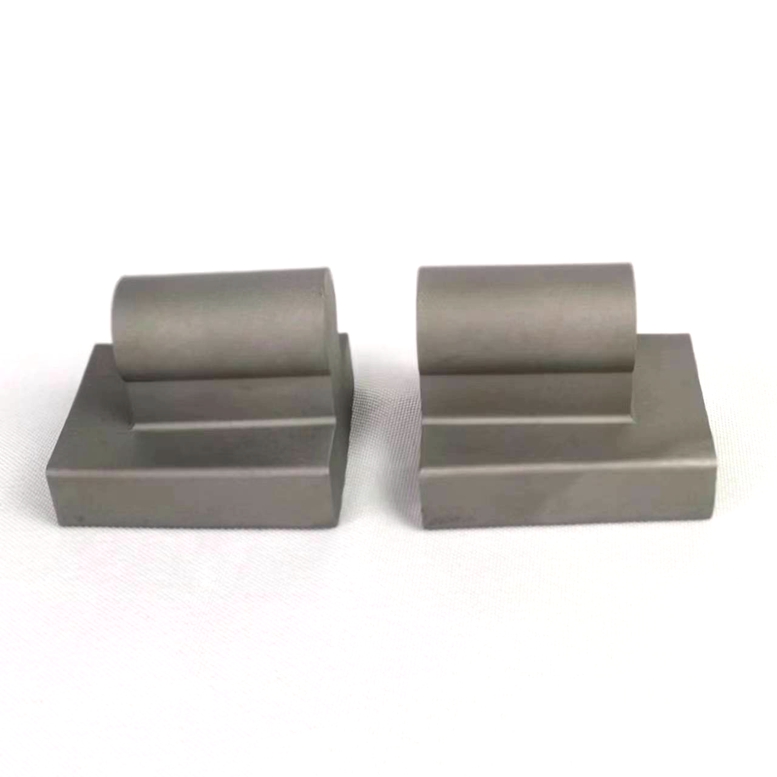

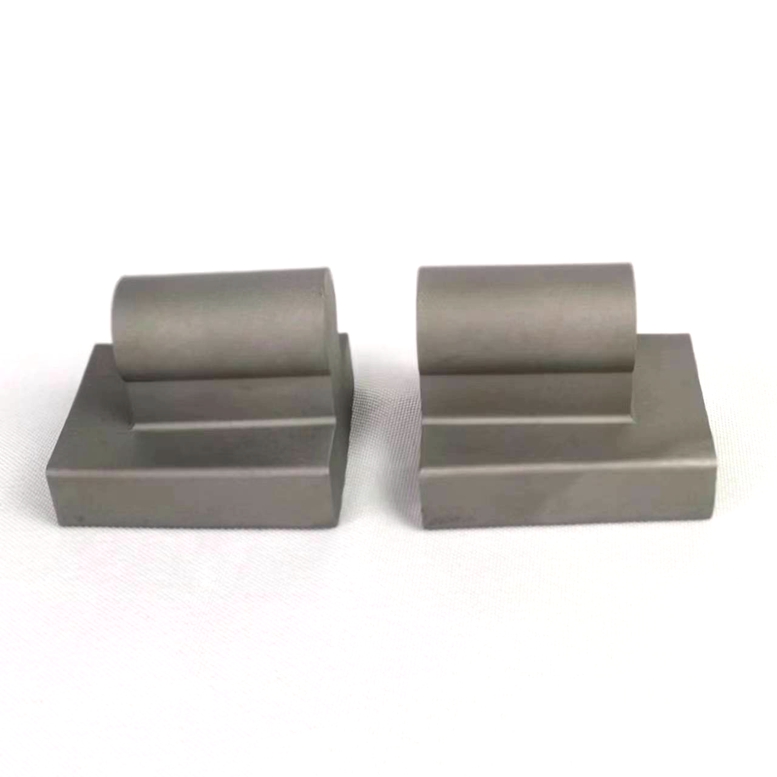

Tungsten Edge Block,

Side Stud, and

Hpgr Hard Alloy Pins. As a leading manufacturer and supplier, we are committed to providing top-notch products that meet your diverse industrial needs. Choose us for reliable solutions and exceptional service.