Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

1.4 Reason Four

(1) Cause: Low working pressure and operating current of the roller press

(2) Impact Analysis:

The content of fine powder (<80um) produced by the material being pressed varies with the operating pressure of the roller press, which directly affects the system's output, quality, and power consumption indicators for grinding. Reasonably increasing the working pressure of the roller press can enhance the content of fine powder (<80um) in the extruded material. Apart from the previously discussed factor of finer incoming material, the following aspects also contribute to this phenomenon:

(3) Solutions:

① The first three points are related to factors before the material enters the roller press. The following measures can be taken to maintain relatively stable material flow and pressure:

② The opening ratio of the oblique insert plate for material flow control on the roller press should be adjusted to maintain a roller gap ≥0.02D (D-roller diameter in mm) and ensure that the operating currents of the main motors reach 60% to 80% of their rated values, with stable working pressure (e.g., 7.5 MPa to 9.0 MPa). This parameter also directly affects the power output of the roller press. Depending on the material grinding characteristics and on-site operating parameters, the opening ratio of the oblique insert plate for material flow control is generally around 50% to 80%, varying among different enterprises.

(4) Case Study: A unit's 160-140 roller press originally had a vertical feeding pipe with dimensions of 1200mm×600mm. Due to intermittent material flow within the pipe, the site experienced significant dust, ineffective material pressure, and poor material extrusion effects. The specific surface area of the incoming material was 150 m2/kg to 160 m2/kg, and the operating working pressure was 7.5 MPa to 8.0 MPa. During a winter overhaul, an investment of 5,000 yuan was made to modify the feeding pipe, reducing its size to 600mm×600mm and replacing the feeding gate valve. After the modification, the material within the pipe flowed continuously, material pressure increased, enabling overfeeding of the roller press, eliminating dust emissions, and improving extrusion effects. The specific surface area of the incoming material rose to 170 m2/kg to 180 m2/kg, and the operating working pressure of the roller press reached 8.0 MPa to 9.0 MPa.

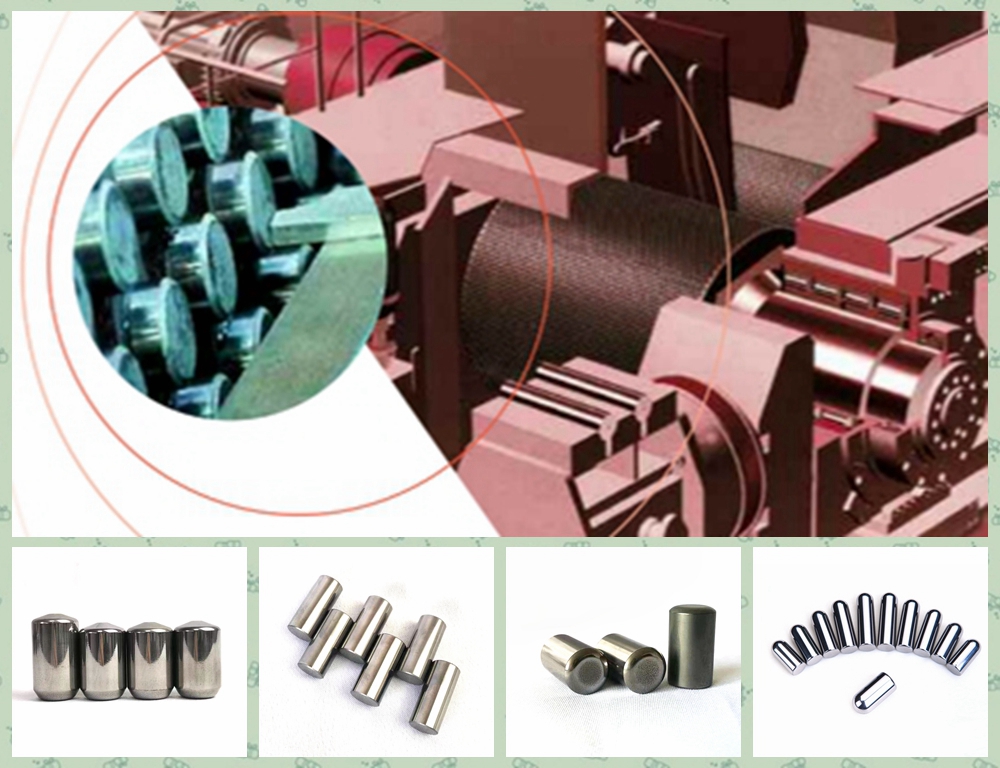

Zigong Tianyi Industry Co., Ltd. stands as a preeminent manufacturer and supplier of premium-grade products within the realm of high-pressure roller press machinery. Our comprehensive product line encompasses essential components such as Hard Alloy Pins, edge blocks, cheek plate, and wear-resistant blocks, tailored for durability and longevity. Furthermore, we specialize in sand-making machinery essentials like Rotor Tip Set, backup tip sets, and Distributor Plate, ensuring efficient and reliable performance. Our offerings also extend to advanced cutting solutions, featuring tungsten Carbide Cutting Tools, carbide inserts, and finish Carbide Boring Head, designed to meet the most demanding industrial standards.

September 20, 2024

September 13, 2024

Talisman Mining has confirmed that it has made a greenfield base metal-precious metal discovery at the Durnings prospect of its Lachlan exploration project in central New South Wales. On the north...

Bolivia and China are actively expanding cooperation in the field of mining. Recently, Chinese Ambassador to Bolivia Wang Liang has called on the President of the National Lithium Company of Bolivia...

Argentina's Ministry of Mines expects the country's copper exports to increase to $5 billion by 2030, when seven projects will come on line, according to the BNAmericas website. The seven projects,...

According to the Mining.com website, citing Reuters, the world's largest copper producer, Chile's National Copper Commission (Cochilco), released data on Friday showed that the country's copper...

Email to this supplier

September 20, 2024

September 13, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.