Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

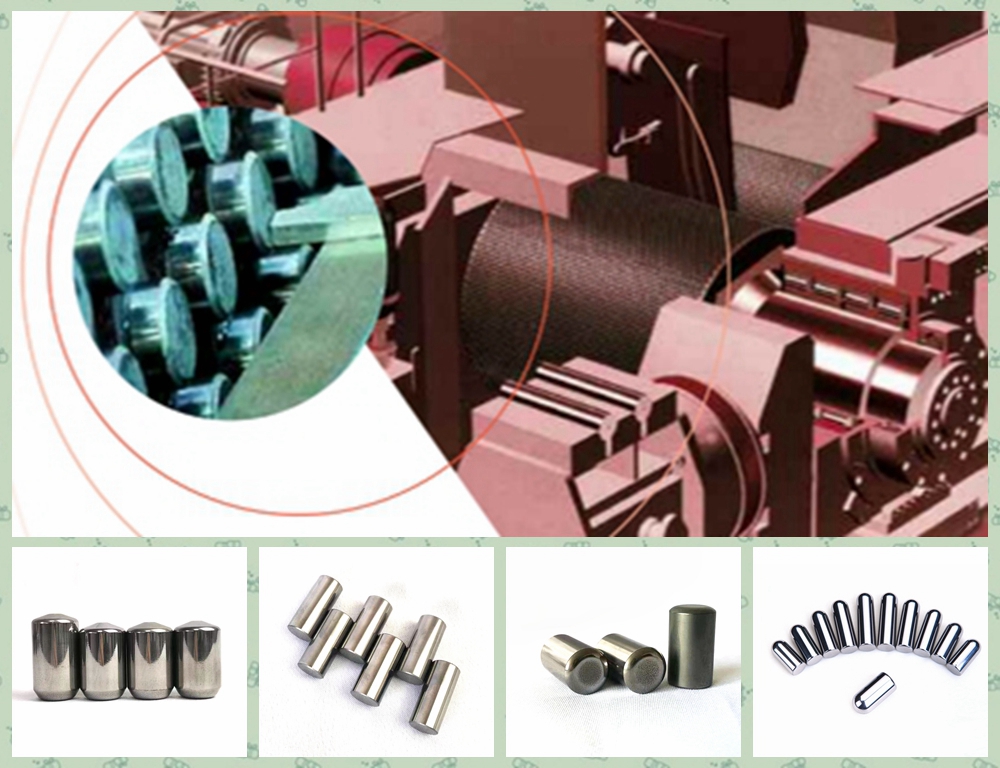

The ultimate source of torsional vibration in roller presses caused by fine-grained materials is material segregation. During the feeding process of roller presses, if there are too many fine-grained materials, the fine-grained materials mixed in the larger-sized materials will not enter the feeding system of the roller press uniformly with the coarse-grained materials, but will separate from each other under the action of material segregation: coarse materials roll, while fine materials bridge! Fine particles accumulate and stagnate in the bin while the equipment operates normally and stably, with good extrusion effects.

When the accumulation of fine-grained materials reaches a certain level, they collapse and pour down. At this time, only fine-grained materials are compressed in the pressure zone between the two grinding rolls of the roller press, and slippage occurs between the fine-grained materials, causing pulsating changes in torque and thus torsional vibration.

Solutions:

Low Bin Level Operation: Limit the material level at the outlet of the weighing bin to form an empty bin but with a full material chute. Since the bin is empty, there is no space for segregation and accumulation of fine materials, which can effectively inhibit material segregation. The full material chute can still form a material column to ensure that the material pressure meets the over-saturated feeding requirements of the roller press. The specific operation method is to empty the material in the weighing bin and gradually raise the material level when the empty material chute forms dust.

At this time, it is necessary to control the lifting speed of the material level to avoid overcorrection. When the dust just disappears, it indicates that the material chute is full but the weighing bin is still empty. At this time, the material level value displayed on the digital display of the weighing sensor in the roller press system control cabinet can be used as the system balance point to stabilize the material level. This method is suitable for mixed materials with a particle size of 1-2 mm, a certain hardness, and still requiring extrusion.

Adjust the Original Roll Gap: When torsional vibration occurs in the roller press, the working roll gap between the two grinding rolls is significantly reduced due to the filling of fine-grained materials in the pressure zone. The working torque of the grinding rolls fluctuates drastically due to pulsating changes, resulting in extremely unstable operating currents of the main motor. We can observe that the reduction in the working roll gap is a characteristic that can be utilized. We can adjust the original roll gap to reduce the pressure on fine-grained materials by the grinding rolls and increase the original roll gap.

When fine materials that do not require extrusion pass through, the working roll gap tends to decrease, but the adjustment shim plate controlling the original roll gap prevents the movable roll from entering, and the grinding rolls are in a near-pressure relief state relative to the materials. Fine-grained materials pass through under significantly reduced pressure, eliminating the slippage phenomenon between materials under the pressure of the grinding rolls and thus eliminating torsional vibration.

September 20, 2024

September 13, 2024

Talisman Mining has confirmed that it has made a greenfield base metal-precious metal discovery at the Durnings prospect of its Lachlan exploration project in central New South Wales. On the north...

Bolivia and China are actively expanding cooperation in the field of mining. Recently, Chinese Ambassador to Bolivia Wang Liang has called on the President of the National Lithium Company of Bolivia...

Argentina's Ministry of Mines expects the country's copper exports to increase to $5 billion by 2030, when seven projects will come on line, according to the BNAmericas website. The seven projects,...

According to the Mining.com website, citing Reuters, the world's largest copper producer, Chile's National Copper Commission (Cochilco), released data on Friday showed that the country's copper...

Email to this supplier

September 20, 2024

September 13, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.